Support center +91 97257 89197

Logistics SolutionMarch 19, 2024

Revolutionizing Cold Chain logistics with IoT Technologies

Introduction

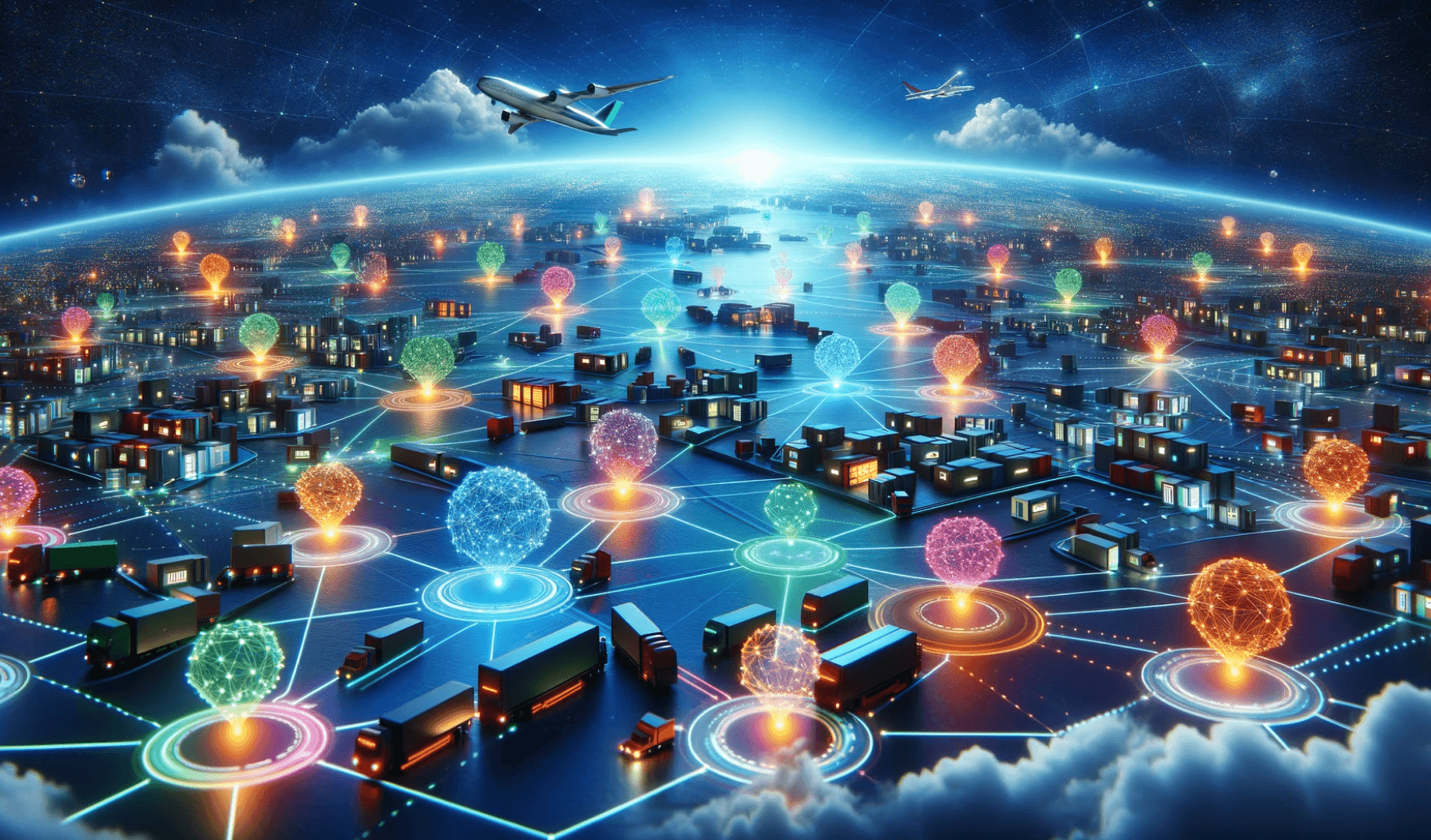

The global economy relies heavily on the seamless operation of cold chain logistics to deliver temperature-sensitive products in pristine condition. This intricate process, vital for industries such as pharmaceuticals, food, and chemicals, faces immense challenges ranging from maintaining strict temperature controls to ensuring real-time visibility across the supply chain. Traditional methods often fall short in meeting these demands, leading to significant losses. However, the advent of the Internet of Things (IoT) is set to revolutionize this sector by introducing unprecedented levels of efficiency, transparency, and reliability.

The Role of IoT in Cold Chain Logistics

IoT stands at the confluence of connectivity and intelligence, bringing about a paradigm shift in how logistics operations are monitored and managed. In the realm of cold chain logistics, IoT technologies offer a comprehensive solution for tracking, controlling, and optimizing the storage and transportation of temperature-sensitive goods. The real-time data generated by IoT devices provides actionable insights, enabling stakeholders to make informed decisions, prevent losses, and ensure compliance with regulatory standards.

Key IoT Technologies Transforming Cold Chain Logistics

Temperature and Humidity Sensors

These sensors are the linchpins of IoT-enabled cold chain logistics. Deployed within transportation units and storage facilities, they provide continuous monitoring of environmental conditions, ensuring that products remain within their required temperature and humidity ranges throughout the supply chain.

GPS and RFID for Tracking and Tracing

IoT enhances the traceability of goods through GPS and RFID technologies. GPS offers precise location tracking of shipments, while RFID tags provide granular details about the product's journey, from origin to destination. This level of visibility is crucial for optimizing routes, managing inventory, and responding swiftly to any deviations or disruptions in the supply chain.

Automated Alerts and Notifications

One of the most significant advantages of IoT in cold chain logistics is the ability to set up automated alerts for temperature deviations, unauthorized access, or delays in transit. These notifications enable immediate corrective actions, minimizing the risk of spoilage or damage to sensitive products.

Data Analytics for Predictive Maintenance and Decision-Making

IoT devices generate vast amounts of data that, when analyzed, can reveal patterns, predict potential system failures, and suggest optimizations. This predictive capability allows for proactive maintenance of equipment, reducing downtime and extending the lifespan of critical infrastructure.

Implementation Strategies

Integrating IoT into existing cold chain operations requires a strategic approach. It begins with a thorough assessment of current logistics practices, identifying areas where IoT can bring the most value. The next steps involve selecting the right mix of technologies, ensuring interoperability, and deploying them in phases to monitor effectiveness and make necessary adjustments. Addressing challenges such as upfront costs, technological compatibility, and workforce training is crucial for a smooth transition.

Future Trends in IoT and Cold Chain Logistics

The future of cold chain logistics with IoT is promising, with emerging technologies like AI, machine learning, and blockchain poised to further enhance the capabilities of IoT systems. AI and machine learning can offer more advanced predictive analytics, while blockchain can provide an immutable ledger for all transactions, ensuring greater transparency and security in the supply chain.

Case Studies: IoT in Action

Real-World Applications

The practical application of IoT technologies in cold chain logistics has led to notable successes across various industries. One such example is a pharmaceutical company that implemented IoT sensors for real-time temperature monitoring during the transport of vaccines. This ensured the integrity of the vaccines, significantly reduced spoilage rates, and improved compliance with health regulations. Another case is a global food distributor that integrated GPS and temperature sensors within their fleet, leading to optimized routes, reduced energy consumption, and a drastic reduction in perishable food wastage.

Overcoming Implementation Challenges

Technological Integration

One of the primary hurdles in adopting IoT in cold chain logistics is integrating new technologies with existing systems. This often requires significant upgrades or replacements, entailing considerable investment. Overcoming this challenge involves a phased implementation strategy, starting with pilot projects to demonstrate ROI and gradually expanding IoT integration across the supply chain.

Cost Consideration

The initial setup cost for IoT infrastructure can be substantial. However, businesses need to weigh these costs against the long-term savings and efficiency gains. Utilizing IoT as a service (IoTaaS) models can also mitigate upfront expenses, offering a scalable and flexible approach to adoption.

Data Security and Privacy

With the increased use of IoT devices, data security becomes a paramount concern. Protecting sensitive information about logistics operations and product whereabouts requires robust encryption protocols and secure data storage solutions. Regular audits and adherence to international data protection standards can help in safeguarding this data.

Skilled Workforce

The successful implementation of IoT technologies also hinges on having a workforce skilled in IoT operation and data analysis. Investing in training and development is essential to equip employees with the necessary skills to harness the full potential of IoT in logistics.

Future Trends in IoT and Cold Chain Logistics

AI and Machine Learning Enhancements

The integration of AI and machine learning with IoT devices is set to offer even more sophisticated analytics, predictive maintenance, and decision-making capabilities. For example, machine learning algorithms can predict potential system failures or optimize routes based on historical data, traffic patterns, and weather conditions.

Blockchain for Enhanced Transparency

Blockchain technology offers a promising addition to IoT in cold chain logistics by providing an immutable record of all transactions within the supply chain. This enhances transparency, builds trust among stakeholders, and ensures compliance with regulatory standards.

Sustainable and Green Logistics

As environmental concerns become more pressing, IoT technologies are being leveraged to develop more sustainable logistics practices. This includes optimizing routes for fuel efficiency, monitoring energy consumption in warehouses, and reducing waste through improved product integrity.

Conclusion

The integration of IoT technologies into cold chain logistics represents a significant leap forward in ensuring the safe, efficient, and reliable transport of temperature-sensitive products. While challenges exist, the potential benefits in terms of cost savings, operational efficiency, and environmental impact make IoT an indispensable tool in the modern logistics landscape.

As the industry continues to evolve, staying informed about and adopting the latest technological advancements will be crucial for companies looking to maintain a competitive edge and meet the growing demands of global supply chains.

TLDR

Explore how IoT technologies are revolutionizing cold chain logistics by enabling real-time monitoring, predictive analytics, and enhanced transparency, leading to improved efficiency and reduced waste.

FAQs

Cold chain logistics refers to the temperature-controlled supply chain necessary for preserving and transporting products that are sensitive to temperature variations, such as food, pharmaceuticals, and chemicals.

IoT improves cold chain logistics by providing real-time temperature monitoring, location tracking, automated alerts, and data analytics, which enhance decision-making and operational efficiency.

Key IoT technologies in cold chain logistics include temperature and humidity sensors, GPS and RFID for location tracking, IoT-enabled vehicles, and data analytics platforms for insightful decision-making.

The benefits include improved product integrity, reduced wastage, enhanced supply chain transparency, cost savings, and the ability to respond proactively to potential issues.

Work with us